The NWS Rotary drum filters are specifically designed and manufactured to cater to the needs of the aquaculture industry. The primary objectives of developing this filter series were to minimize maintenance and reduce water and energy consumption. Keeping these aims in mind, the engineers at NWS created a thoughtful construction series of drum filters that boast excellent manufacturing quality and a perfectly fitting controller. Some of the benefits of these filters include a clever drive system, robust frame construction, and an intelligent control unit that saves water and energy. Thanks to these advantages, the NWS aquaculture drum filters offer highly efficient filtration with minimal manual maintenance.

The drum filter operates on the principle of mechanical trapping of particles. The water which contains suspended solids flows through the filter screen where the particles are trapped. The control unit detects the clogging of the filter mesh and activates the backwashing process to clean the filter mesh and remove the dirt particles through the wastewater outlet.

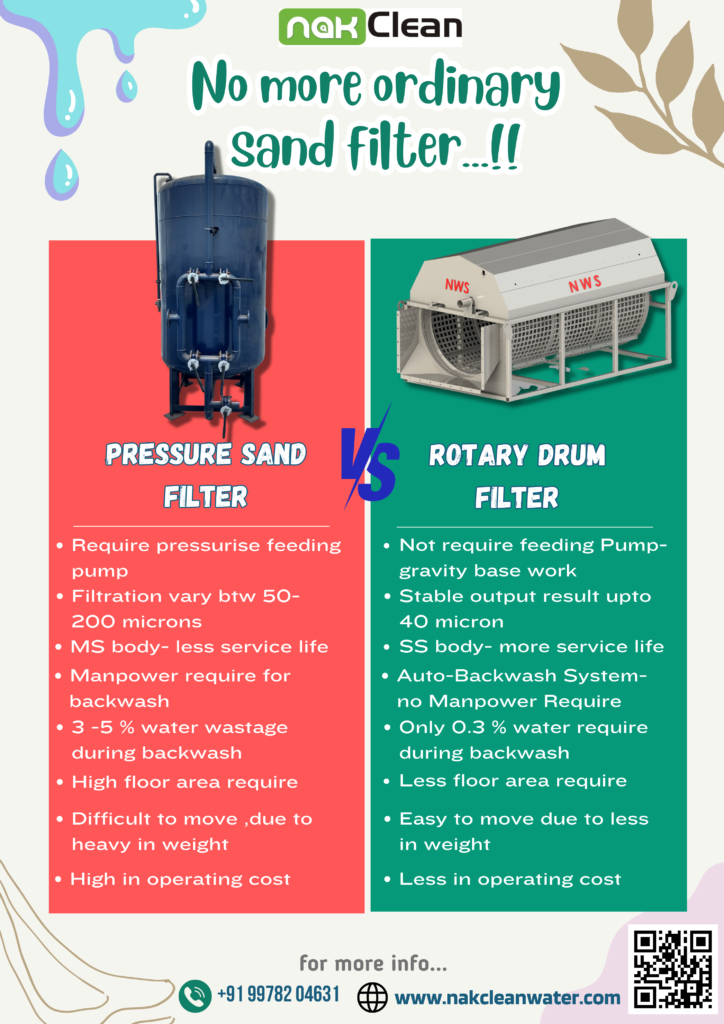

Microscreen drum filters are considered the most advanced technology for filtering particles in aquaculture applications. The technology offers many benefits, such as the automatic removal of solid waste and a well-designed mechanical base, making it perfect for various applications.

Reliable fine screening with maximum separation efficiency Operating reliability for membrane bioreactors Maximum COD / BOD5 reduction rates

Drum filters are used in a wide field of applications:

SUSTAINABLE FILTRATION WITHOUT CHEMICALS

The design of modern wastewater treatment plants by Nakclean Water has highlighted the benefits of primary filtration in pretreatment processes. Primary filtration helps to achieve a high level of treatment while reducing energy requirements and plant footprint, resulting in a lower overall carbon footprint. The primary filtration process also yields more valuable sludge than conventional primary sedimentation designs. Removing solids during the early stages of the treatment process improves the efficiency of downstream biological stages. The sludge produced during primary filtration contains more energy, which can be utilized in the digestion chamber.

Contact Us