In the dissolved-air flotation system, a liquid stream saturated with pressurized air is forcefully added to the flotation unit where it vigorously mixes with the incoming feed. As the pressure returns to the atmosphere, the dissolved air forcefully comes out of the liquid, forming fine bubbles that forcefully bring fine particles with them. These forcefully rise to the surface and are then forcefully removed by a skimmer.

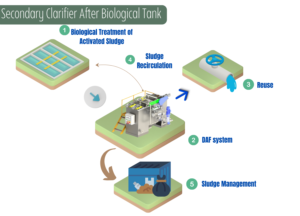

Dissolved air flotation (DAF) is a proven and effective physical/chemical technology that has been utilized to treat a variety of industrial and municipal process and wastewater streams. DAF systems have been widely adopted for the removal of oils & greases and suspended solids with several treatment goals in mind, including product recovery and reuse, pretreatment to meet sewer discharge limits, reduction of loading on downstream biological treatment systems, polishing of biological treatment effluent, and thickening of biosolids.

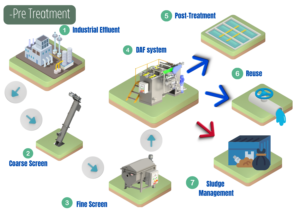

One of the most common DAF applications is for the pre-treatment of industrial wastewater to remove suspended solids, oils, and greases before discharge into a municipal sewage or biological treatment system. For instance, an industrial discharger may utilize a Pretreatment DAF to meet specific limits for oil and grease and/or suspended solids set by industries and government municipalities (e.g., to meet a discharge limit of 100 mg/L O&G, etc.). In some cases, an industry may need to use a Pretreatment DAF to eliminate contaminants (e.g., product solids, oils and greases, heavy metals, etc.) that would adversely impact a downstream biological wastewater treatment system.

In most instances, the wastewater contaminants need to be chemically flocculated for the floatation system to remove them. Pretreatment DAF is extensively deployed in almost every industry and has proven to be highly effective in removing biological solids from wastewater streams. Some of the advantages over traditional gravity clarification systems include a smaller footprint and faster implementation, higher sludge solids content (4%TS vs. 1%TS), resulting in a considerably lower sludge volume, the ability to handle bulking solids that tend to float, and more reliable effluent quality.

To obtain further information, please fill out this form to receive a response from our experts.

DAF is a water treatment process that removes impurities from wastewater in various industries. Advantages include a reduced footprint, lower compliance costs, high efficiency, high-quality treated water, and increased rates of water reuse. The process is highly effective, removing up to 99% of impurities, and produces less waste and requires less maintenance than traditional methods. DAF systems can be easily integrated into existing wastewater treatment plants, making them cost-effective.

Dissolved air flotation clarifies wastewater by dissolving air in the wastewater under pressure, releasing the air in a flotation tank, and causing tiny bubbles to adhere to suspended matter, causing it to float to the surface where it can be removed by a skimming device. Coagulant/flocculants are added to improve solids removal by encouraging suspended solids and colloidal particles to clump together.

DAF technology is widely used in industries such as

DAF removes contaminants from seawater in desalination plants and from food and beverage production wastewater. It removes ink and solids from wastewater in paper and pulp production and minerals in mining. In oil and gas production, it separates oil and water.

DAF technology offers high removal efficiency, flexibility, and a small footprint compared to other wastewater treatment processes. It can remove up to 90% of contaminants and treat a wide range of wastewater types. DAF systems require less space than other processes and yield sludge at 5% dry solids content. High-intensity DAF is used to pre-treat seawater against algal blooms. A mixed buffer tank is recommended to avoid downstream process problems caused by variable sludge solids content and for degassing DAF sludge.

Despite its many advantages, dissolved air flotation (DAF) technology also has some disadvantages, including:

For high-rate dissolved air flotation (DAF), sludge treatment, and industrial applications, required recycle rates may be several hundred percent of the throughput. Air solubility in water is temperature-dependent, which may also be a factor in selecting a DAF process, since sludges and industrial effluents may be warm, as may seawater used by those countries which desalinate for drinking water treatment.

A Dissolved Air Flotation (DAF) system is a remarkable wastewater treatment process that utilizes the power of air to purify water from various contaminants. It is a highly sophisticated method that involves the separation of suspended solids, oils, and other impurities from water. By introducing air into the water, the DAF system creates countless tiny air bubbles that attach to the impurities and lift them to the water’s surface. The floating particles are then removed by a skimming mechanism, leaving behind crystal-clear water that is safe for discharge or reuse. DAF systems are widely used in industries that produce high volumes of wastewater, including the food and beverage, oil and gas, and pulp and paper industries. They are known for their remarkable efficiency, reliability, and ease of operation, making them a popular choice for many different applications.

DAF removes pollutants, solids, and oils from wastewater, treats industrial and municipal wastewater, and improves drinking water quality.

Dissolved air flotation is a remarkable solution that achieves exceptional results by removing up to 99% of oil from water.

In the context of wastewater treatment, the cost of a Dissolved Air Flotation (DAF) system is subject to considerable variation, contingent on its capacity and the characterizing features of the wastewater. In this regard, smaller-scale DAF systems may be obtained for as little as 5,00,000 RS, while larger-scale counterparts may require several lakhs of investment.

Dissolved air flotation (DAF) units have the potential to last for several years, provided that they are subject to proper maintenance, regular cleaning, and inspection. In order to maintain the longevity of these systems, it is imperative that they are subject to periodic examinations and cleaning procedures. Timely and efficient maintenance measures can not only extend the life of such units but also ensure that they operate optimally throughout their lifespan. Therefore, it is of utmost significance that these systems are maintained in pristine condition to guarantee optimal functionality and performance.

DAF technology is commonly used in various industries for treating industrial wastewater. It effectively removes suspended solids, oil, and grease generated during industrial processes. The process involves injecting air bubbles into wastewater, which attach to the suspended particles and float them to the surface for easy removal. The treated water can then be discharged or reused in industrial processes.

Dissolved Air Flotation (DAF) units are considered as a potential solution for the treatment of sewage. However, their suitability for large-scale municipal wastewater treatment remains a topic of debate. Nonetheless, DAF can be utilized as a pre-treatment measure to effectively eliminate solids and other contaminants prior to further treatment.

Dissolved air flotation (DAF) is a highly effective method for removing organic matter and other pollutants from wastewater with high levels of contamination, particularly for the reduction of biochemical oxygen demand (BOD). The DAF process involves the introduction of air bubbles under pressure, which attach to the suspended particles, causing them to float to the surface of the water where they can be easily removed. This method is widely used in various industrial and municipal applications due to its efficiency and reliability. It is important to note that the effectiveness of the DAF process may vary depending on the specific characteristics of the wastewater being treated, and it may require modifications to achieve optimal results.

Dissolved Air Flotation (DAF) is a widely used clarification process in wastewater treatment that capitalizes on the use of micro air bubbles to attach and float the flocculated particles and suspended solids to the water surface for removal. In contrast, sedimentation is a process that removes settled solids from the bottom of a wastewater treatment tank. The DAF process is particularly useful when dealing with high turbidity, algae-rich water, and when dealing with colloidal and oily wastewater. The removal of suspended solids from wastewater is a critical process in the treatment of industrial and municipal wastewater. The DAF process is an effective alternative to traditional sedimentation processes that offer a more efficient and cost-effective means of removing solids from wastewater streams.

The pressure range for dissolved air flotation varies between 20 to 60 pounds per square inch (psi), contingent on the specific system and application under consideration. It is essential to note that these values are subject to variation, and may differ depending on the unique conditions present.

The Dissolved Air Flotation (DAF) process entails the introduction of a chemical coagulant into wastewater to facilitate the formation of larger particles, which are subsequently easy to remove. The process involves the injection of air, which creates tiny bubbles in the mixture that attach themselves to the larger particles. The bubbles, in turn, cause the particles to float to the surface, where they are easily skimmed. This process is highly effective in the removal of contaminants from wastewater, making it a popular and sustainable solution in the treatment of industrial wastewater.

Dissolved Air Flotation (DAF) generates air bubbles under 4-6 atmospheres pressure, typically ranging in size from 10-100 µm with an average diameter of 40 µm. The pressure difference across the nozzle system affects bubble size the most. Smaller bubbles increase the surface area for impurities to attach to, but if too small, they may not capture impurities effectively.

Contact Us